English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski

How Do Promotional Materials Build Trust and Drive Sales in 2026?

Abstract

If your flyers disappear, your catalogs get ignored, and your “premium” packaging still feels cheap, the problem usually isn’t printing—it’s planning. This guide breaks down how to choose the right Promotional Materials for your goal, avoid common production traps, control quality without stress, and pick a printing partner you can rely on. You’ll get practical checklists, a decision table, and a clear path from idea to delivery—without wasting budget or time.

Table of Contents

- Outline

- Why Promotional Materials still matter

- Customer pain points and quick fixes

- A simple strategy before you print

- Format, paper, and finish decisions

- Quality control without the headache

- Choosing a printing partner

- Budgeting and performance tracking

- FAQ

- Next steps

Outline

- Define the job your Promotional Materials must do (attention, education, conversion, retention).

- Match the format to the moment: handout, shipment, showroom, event, or sales meeting.

- Lock essentials early: messaging hierarchy, brand rules, sizes, quantities, and deadlines.

- Choose materials and finishes based on feel, durability, and compliance—not vibes.

- Run production with clear proofs, tolerances, and checkpoints to prevent surprises.

- Evaluate partners with a repeatable scorecard so you can scale confidently.

Why Promotional Materials still matter

People scroll fast. They forget faster. Physical experiences slow the moment down—and that’s exactly why Promotional Materials keep winning when brands need trust, clarity, and action.

- They create “realness.” A well-made brochure or box signals legitimacy in a way a generic landing page can’t.

- They reduce decision stress. Clear specs, comparisons, and use-cases help buyers choose without a sales call.

- They travel. A catalog gets passed around a team. A great package gets photographed. A hang tag stays with the product.

- They help sales teams. A structured deck is useful, but a tactile sample kit often closes the deal.

Reality check

“More printing” doesn’t equal “more results.” The most effective Promotional Materials are engineered like a product: designed for a specific user, at a specific moment, to trigger a specific next step.

Customer pain points and quick fixes

If you’ve ever felt burned by inconsistent color, delayed shipments, or pieces that look good on screen but cheap in hand—welcome to the club. Here are the most common problems buyers face, and what actually fixes them.

-

Pain point: “It looked premium in the mockup, but arrived flimsy.”

Fix: Choose paper weight and structural design based on handling. Ask for a physical sample or a material swatch set before mass production. -

Pain point: “Colors don’t match our brand.”

Fix: Provide brand color references, specify acceptable tolerances, and require a press proof for critical items. -

Pain point: “The copy is fine, but people don’t respond.”

Fix: Rebuild the hierarchy: one promise, three proof points, one action. Cut decorative text. Increase clarity. -

Pain point: “We missed the event deadline.”

Fix: Work backward: design freeze date → proof date → production window → shipping buffer. -

Pain point: “We overspent and can’t explain the ROI.”

Fix: Track with simple mechanisms: unique QR codes, offer codes, dedicated landing pages, sales team attribution.

A simple strategy before you print

Great Promotional Materials start with a sharp job description. Before you debate gloss vs matte, answer these five questions.

| Question | Why it matters | Practical example |

|---|---|---|

| What’s the one action you want? | Design and copy should point to a single next step. | “Request a quote,” not “Learn more / Follow us / Subscribe / Call us.” |

| Where will it be used? | Environment drives size, durability, and finish. | Trade show handouts need speed-scannable layouts and sturdy stock. |

| Who reads it? | Different roles care about different proof points. | Engineers want specs; procurement wants lead time and consistency. |

| What’s your credibility? | Buyers need evidence, not adjectives. | Add certifications, process photos, QC steps, and real use-cases. |

| What must never go wrong? | Decide non-negotiables early to avoid rework. | Color accuracy for logo, barcode readability, die-cut alignment, safety text. |

A helpful rule

If your Promotional Materials need to “explain everything,” they probably explain nothing. Prioritize: one promise → proof → product clarity → one action.

Format, paper, and finish decisions

Choosing formats is less about “what looks nice” and more about “what gets used.” Use the table below to match the job to the right kind of Promotional Materials.

| Your goal | Best formats | Why it works | Common mistake to avoid |

|---|---|---|---|

| Fast awareness at events | Flyers, postcards, mini-brochures | Quick scan, easy distribution | Too much text, tiny fonts, no clear action |

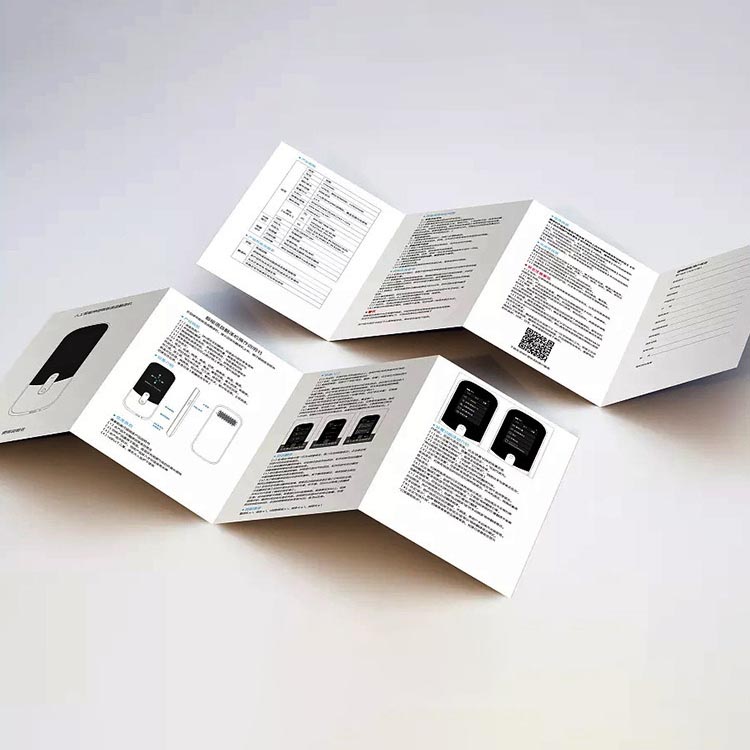

| Educate and qualify leads | Product brochures, spec sheets, fold-out guides | Structured information, easy comparison | Generic claims without proof points |

| Premium brand positioning | Rigid boxes, gift sets, branded sample kits | High tactile value, “keep-worthy” | Over-finishing that increases cost without benefit |

| Retail conversion | Hang tags, labels, inserts, countertop displays | Decision support at shelf | Unreadable type, poor adhesive choice |

| Repeat purchase | Thank-you cards, care guides, loyalty inserts | Extends experience after delivery | Missing practical instructions customers actually need |

Paper and finish aren’t decoration—they’re communication. Here’s a simple way to choose.

- Matte finishes: calmer, modern, easier to read under bright light; great for technical or minimalist brands.

- Gloss finishes: vibrant and punchy; useful for photography-heavy catalogs, but can reflect harshly.

- Soft-touch lamination: premium feel; ideal for boxes and covers, but confirm scratch resistance if shipping is rough.

- Spot UV / foil stamping: draws attention; best when used selectively to highlight one key element.

Pro tip

If durability matters (shipping, warehouses, outdoor events), test your Promotional Materials like a customer would: rub, bend, stack, drop, and expose them to light. “Looks good on day one” is not the same as “looks good after handling.”

Quality control without the headache

Most quality disasters happen because expectations were never written down. You don’t need to be a print expert—you just need a simple control system. Use this workflow to keep your Promotional Materials consistent across runs.

- Set a “design freeze” date. Late edits are the #1 cause of errors and missed deadlines.

- Choose the right proof type. For critical colors or luxury packaging, a press proof is worth it.

- Confirm structural details. For boxes and die-cuts, request a physical mockup or a clear dieline review checklist.

- Define acceptance standards. What’s acceptable for color variation, alignment, and finishing? Put it in writing.

- Run pre-shipment checks. Ask for photos/video of random samples, carton markings, and counts before dispatch.

A quick checklist you can copy into your purchase order

- Size, quantity, and version control (V1 / V2 / language variants)

- Paper type and weight, finish type, and special processes (foil, UV, emboss)

- Color references and priority areas (logo, product photo, background)

- Barcode/QR readability requirements (minimum size, contrast)

- Packing method and carton labeling requirements

- Timeline: proof approval → production → shipping

Choosing a printing partner

Your printing partner affects more than quality—they affect speed, stress levels, and your ability to scale. When comparing suppliers for Promotional Materials, use a scorecard instead of gut feel.

| What to evaluate | What “good” looks like | What to ask |

|---|---|---|

| Communication | Clear timelines, fast answers, proactive risk warnings | “Who owns my project day-to-day, and what’s the response time?” |

| Sampling capability | Material swatches, mockups, controlled proof process | “Can you provide samples that match the final finish?” |

| Process control | Documented checkpoints, consistent reprint performance | “How do you keep color and alignment consistent across runs?” |

| Customization range | Flexible sizes, finishes, inserts, and structural options | “What customization options do you recommend for my use case?” |

| Reliability | Realistic schedules, packaging protection, shipment visibility | “What’s your standard lead time, and how do you handle rush orders?” |

If you’re exploring specialized providers, you may come across companies such as Guangdong Dicai Printing Co., Ltd.. Regardless of who you choose, the best partners share the same habits: they clarify requirements early, surface risks before they become delays, and treat your brand consistency like a system—not a lucky outcome.

Budgeting and performance tracking

The best Promotional Materials feel effortless to the customer—but behind the scenes, they’re cost-managed deliberately. Here’s what usually drives pricing, and where you can optimize without hurting quality.

- Quantity breaks: Unit cost drops with scale, but only if you’ll actually use inventory before it becomes outdated.

- Paper and structure: Heavier stock and rigid construction increase cost, but often reduce returns and damage.

- Finishes: Foil, embossing, and specialty coatings add impact—use them to highlight one key element, not everything.

- Versions: Multiple languages or SKUs can be efficient if planned as a modular system (common core + variable panels).

- Shipping and packing: Protective packing may cost more upfront, but prevents expensive reprints.

Simple tracking ideas (no complicated tools required):

- Use a unique QR code for each channel (event, distributor, direct mail) to see what actually drives inquiries.

- Add a short offer code on inserts to attribute repeat purchases.

- Ask sales teams to mark which piece helped move a deal forward (one checkbox in your CRM is enough).

FAQ

Q: What are the most effective Promotional Materials for buyers?

A: Start with a structured product brochure or spec sheet (clarity), then add a sample kit or premium folder (trust). Buyers often need evidence they can share internally, so prioritize comparability, certifications/process proof, and clear next steps.

Q: How do I prevent color mismatch across reprints?

A: Provide clear brand color references, define priority areas (logo, hero imagery), and use consistent proofing standards.

For critical items, a press proof or controlled proof workflow reduces surprises.

Q: Is “premium packaging” always worth it?

A: Only if it supports your positioning or reduces friction (damage, returns, trust issues). If your product is value-driven,

smart structure and clear labeling often beat expensive finishes.

Q: How early should I start before an event or launch?

A: A safe baseline is 4–6 weeks for design, proofs, production, and shipping buffers. Complex packaging or multiple versions may need longer.

Work backward from your hard deadline and lock a design freeze date.

Q: What should I send a printer to get an accurate quote?

A: Size, quantity, artwork status (final or draft), paper/finish preferences, structural requirements (if packaging),

and deadline/shipping destination. The more specific you are, the fewer surprise costs appear later.

Next steps

If you want Promotional Materials that look right, feel right, and arrive on time, treat the process like a repeatable system: define the job, pick the right format, document your non-negotiables, and work with a partner who can execute consistently.

Ready to move from “pretty prints” to materials that actually perform?

Share your goal (event, retail, sales, packaging upgrade), quantity, and timeline, and we’ll help you map the most practical options—paper, finishes, structure, and a clean production plan. If you’re considering Guangdong Dicai Printing Co., Ltd. or comparing suppliers, use the checklists above, then contact us to discuss a tailored solution for your next run.

Send Inquiry

-

Email

-

Call Us

-

Address

No. 2, Fuxi Industrial Zone, Chishan Village, Lishui Town, Nanhai District, Foshan City, Guangdong province, China

For inquiries about 3C digital packaging, cosmetic packaging, handbags or price list, please leave your email to us and we will be in touch within 24 hours.

Copyright © 2024 Guangdong Dicai Printing Corporation Co., Ltd. All Rights Reserved.