English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski

Why Is Corrugated Paper Packaging Still the Most Practical Choice for Modern Shipping?

2025-12-31

Abstract

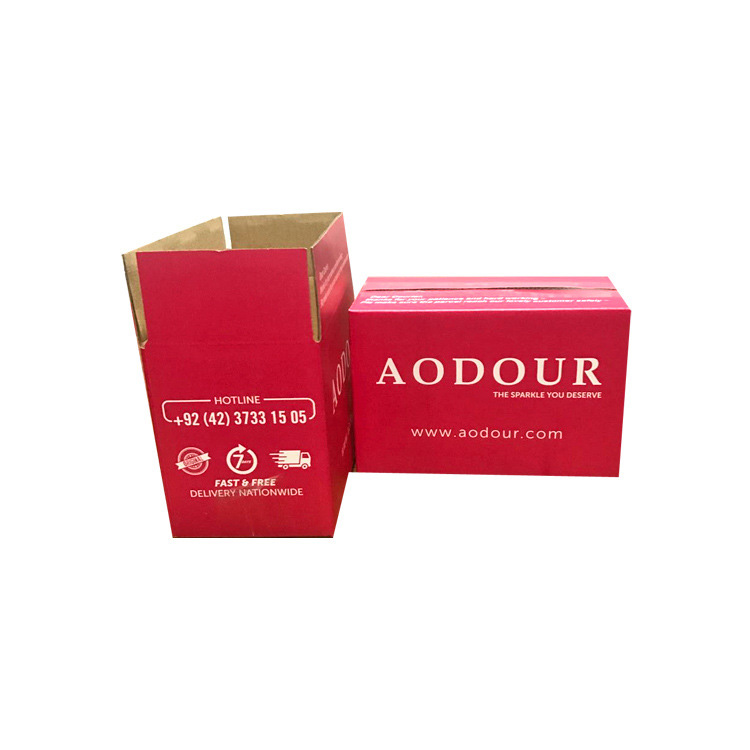

Corrugated packaging looks simple, but the wrong board grade or structure can quietly bleed money through returns, rework, and customer complaints. In this article, I break down the real-world decisions behind Corrugated Paper Packaging: how to match flute type and strength to your product, what to test before scaling, and how to design a box that survives sorting hubs, stacking pressure, humidity, and last-mile handling. You’ll also find a practical specification table, checklists, and an FAQ to help you avoid common (and expensive) mistakes.

Table of Contents

- What pain points does Corrugated Paper Packaging solve?

- What is corrugated, and what actually matters?

- How do I choose the right board strength and flute?

- How do I design a box that survives real shipping?

- How can I reduce total packaging cost without going “thin”?

- How do I balance sustainability with performance?

- What are the most common mistakes buyers make?

- How should I work with a manufacturer for consistent quality?

- FAQ

- Closing thoughts

Outline

- Define the shipping reality: drop risk, stack height, climate, and transit time.

- Translate product risk into board specs: flute, wall construction, and strength targets.

- Lock structure details: style, closures, inserts, and void-fill strategy.

- Run validation: compression, drop, humidity exposure, and pack-out trials.

- Scale with consistency: print control, tolerances, and audit checkpoints.

What pain points does Corrugated Paper Packaging solve?

Most buyers don’t wake up thinking about cartons. They wake up thinking about the consequences: broken products, angry customers, delayed launches, and margins that shrink one “small” packaging decision at a time. The reason Corrugated Paper Packaging stays so widely used is that it solves multiple headaches at once.

- 1) Damage and returns: Corrugated absorbs shock, resists compression, and can be engineered with inserts so fragile items don’t rattle or puncture.

- 2) Freight efficiency: Right-sizing reduces dimensional weight charges, while stronger stacking performance lets you palletize higher with less risk.

- 3) Operational speed: A well-designed box packs faster, tapes faster, labels cleaner, and reduces “special handling” exceptions on the line.

- 4) Brand experience: Print, color, and unboxing structure can make even a simple shipper feel premium and trustworthy.

- 5) Sustainability goals: Corrugated is widely recyclable and can be optimized to use less material without sacrificing performance.

The trick is that corrugated isn’t one thing. A “corrugated box” could mean a lightweight mailer for cosmetics, a heavy-duty master carton for industrial parts, or a retail-ready tray that speeds shelf stocking. Your results depend on how you specify it.

What is corrugated, and what actually matters?

Corrugated board is built from liner sheets with a fluted medium in between. That wavy structure is the secret: it adds stiffness, cushioning, and stacking strength without turning your package into a brick. But when buyers say “make it stronger,” manufacturers need something more concrete than vibes.

| What you should specify | What it controls | Why you should care |

|---|---|---|

| Flute type (A/B/C/E/F) | Thickness, cushioning, print surface | Impacts crush resistance, protection, and how sharp graphics look |

| Wall construction (single/double/triple) | Stacking strength and puncture resistance | Reduces collapse in warehouses and during pallet stacking |

| Strength target (ECT or burst) | Edge compression or puncture/burst performance | Helps prevent crushed corners and panel blowouts |

| Box style (regular slotted, die-cut, mailer, tray) | Assembly speed, protection zones | Structure often matters more than “thicker paper” |

| Environmental exposure | Moisture, humidity, temperature swings | Humidity can weaken board dramatically if you don’t plan for it |

Practical tip: if your product ships through humid regions or sits in non-climate-controlled containers, ask for moisture-aware solutions (coatings, higher-performance liners, or structural changes) rather than just increasing thickness.

How do I choose the right board strength and flute?

Choosing Corrugated Paper Packaging should start from the product and the journey, not from a “standard box” habit. I like to think in three questions: how fragile is it, how heavy is it, and how badly will shipping try to hurt it?

- Fragility: glass, ceramics, electronics, and tight-tolerance parts need cushioning and immobilization.

- Weight: heavier items multiply compression risk, especially when stacked.

- Journey: long-distance, multi-carrier routes, and last-mile delivery usually mean more drops and vibration.

Then translate that into structure: single-wall for many light to mid-weight goods, double-wall for heavier items or rougher handling, and die-cut mailers when you want speed, clean presentation, and better resistance to “squeezes” in parcel networks.

My quick decision rule

If you’re seeing corner crush, don’t automatically jump to “thicker board.” First ask: can I improve fit, add corner protection, change closure, or adjust pallet pattern? Strength helps, but smart structure often fixes the root cause with less cost.

How do I design a box that survives real shipping?

A shipping carton fails in predictable ways: crushed corners, popped seams, punctured panels, or internal movement that turns your product into a wrecking ball. The best corrugated solutions treat the box as a system: board + structure + interior + closure.

- Right-size the internal space: too much empty volume invites movement and damage.

- Use inserts where it counts: partitions, pads, or custom die-cuts can outperform “more bubble wrap.”

- Design for stacking: panel strength and corner integrity matter more than face area.

- Choose a closure strategy: tape pattern, adhesive, or lock-tabs should match weight and handling.

- Plan for labels and scans: smooth label zones reduce misreads and rework.

For high-return categories (beauty, small electronics, subscription boxes), the unboxing moment also matters. Corrugated can deliver a clean “premium” feel through tighter tolerances, crisp printing, and intuitive open features— without needing heavy, expensive materials.

How can I reduce total packaging cost without going “thin”?

The cheapest box on paper is often the most expensive box in reality. Total cost includes damages, labor time, filler usage, storage space, and freight. When you optimize those together, corrugated becomes a lever—not just a line item.

| Cost driver | What to optimize | Typical result |

|---|---|---|

| Dimensional weight | Right-size cartons, reduce void space | Lower shipping charges and less filler |

| Labor | Auto-bottom, easier folds, fewer tape passes | Faster pack-out and fewer errors |

| Damage rate | Better fit + inserts + stronger corners | Fewer returns and replacements |

| Storage | Standardize sizes, ship flat efficiently | Less warehouse clutter and simpler picking |

| Over-specification | Use testing to avoid “just in case” board | Material savings without performance loss |

If you want one high-impact move: run a pack-out trial with your top 3 SKUs by volume. A small reduction in carton dimensions can save more than a large reduction in paper grade. This is where Corrugated Paper Packaging shines—because it’s easy to iterate and scale once you dial it in.

How do I balance sustainability with performance?

Buyers often feel stuck between “eco goals” and “damage prevention.” You don’t have to choose one. Most of the time, the best sustainability win is reducing waste through smarter design. A right-sized, well-performing corrugated system can reduce filler, avoid double-boxing, and cut replacement shipments.

- Minimize void: less space means less filler and fewer damage events.

- Optimize structure: better corner protection can let you reduce overall board weight.

- Use recyclable interiors: molded pulp or paper-based inserts can replace plastic options in many cases.

- Print responsibly: efficient ink coverage and clean layouts reduce rework and scrap.

The practical approach is simple: protect first, then reduce material through testing and iteration. A package that arrives intact is inherently less wasteful than a “greener” one that fails and triggers reshipments.

What are the most common mistakes buyers make?

If you’ve had a frustrating packaging project, odds are it was caused by one of these problems. The good news is they’re fixable—and once you fix them, corrugated becomes predictable instead of stressful.

-

Mistake: Ordering by “box size only.”

Fix: Include strength targets, flute, and use-case details. -

Mistake: Ignoring humidity and storage time.

Fix: Plan for climate exposure and long transit windows. -

Mistake: Over-relying on filler.

Fix: Improve fit and add targeted inserts instead of stuffing space. -

Mistake: No pack-out trial.

Fix: Pilot test before mass production; validate drops and compression. -

Mistake: Underestimating printing requirements.

Fix: Match print method and board surface to the visual standard you need.

How should I work with a manufacturer for consistent quality?

The best outcomes come from treating your supplier like a technical partner, not a commodity source. A good manufacturer will ask about your product, your shipping environment, and your failure history. If they don’t, you may end up paying for surprises later.

When working with Guangdong Dicai Printing Co., Ltd., I recommend bringing a clear “packaging brief” that includes: product dimensions and weight, fragility notes, shipping method (parcel, LTL, FCL), stack height expectations, and your preferred unboxing or retail presentation. That information helps the team recommend flute type, structure, and printing approach that match your reality—so you’re not guessing.

A simple packaging brief you can copy

- Product size, weight, and “break points” (corners, screens, protrusions)

- Average order configuration (single unit, multi-pack, kits)

- Shipping route and carrier style (parcel vs palletized)

- Target unboxing look and branding elements

- Known issues (corner crush, rattle, puncture, scuffed print)

FAQ

- How do I know if my box strength is the real problem?

- If cartons collapse under stacking, corners crush easily, or seams pop during handling, strength may be part of it. But first check fit, closure, pallet pattern, and internal movement—structure issues often create “strength” symptoms.

- Is double-wall always better than single-wall?

- Not always. Double-wall increases stacking and puncture resistance, but it can also add cost and thickness. For many products, a better structure (and less void) beats simply upgrading wall construction.

- What’s the fastest way to cut damage rate?

- Improve immobilization. If the product can move inside the box, vibration and drops become far more destructive. Tight fit plus targeted inserts usually outperform “extra filler.”

- Can corrugated look premium for branding?

- Yes. Clean die-cut edges, tight tolerances, thoughtful opening features, and well-controlled printing can deliver a premium feel without needing heavy materials. The key is aligning board surface and print method with your visual standard.

- What information should I send when requesting a quote?

- Send internal dimensions, product weight, order configuration, estimated monthly volume, printing needs, and shipping method. Include your pain points—damage photos or notes can speed up the right recommendation.

Closing thoughts

Done right, Corrugated Paper Packaging is one of the easiest ways to protect your product, improve customer experience, and reduce hidden costs across shipping and operations. The smartest approach isn’t “make it thicker”—it’s “make it fit, test it, and make it consistent.”

If you want a corrugated solution matched to your product and shipping route, contact us with your product details and target carton size. We’ll help you choose an appropriate structure, board grade, and print approach so your packaging performs the way your customers expect—every single shipment.

-

E-mail

-

Call Us

-

Address

No. 2, Fuxi Industrial Zone, Chishan Village, Lishui Town, Nanhai District, Foshan City, Guangdong province, China

For inquiries about 3C digital packaging, cosmetic packaging, handbags or price list, please leave your email to us and we will be in touch within 24 hours.

Copyright © 2024 Guangdong Dicai Printing Corporation Co., Ltd. All Rights Reserved.